Air compressor filter elements refer to oil filters, air filters, and oil separators. 1. Oil filter element: The function of the oil filter element is to remove metal particles and impurities from the special oil used in air compressors, ensuri...

Contact Us

Air compressor filter elements refer to oil filters, air filters, and oil separators.

1. Oil filter element: The function of the oil filter element is to remove metal particles and impurities from the special oil used in air compressors, ensuring that the oil entering the main unit is extremely clean to protect the safe operation of the main unit.

Oil filter element material: high-precision filter paper.

Oil filter element replacement criteria: Replace when the actual usage time reaches the designed service life.

The designed service life of the oil filter element is typically 2,000 hours. It must be replaced upon expiration. In environments with poor air compressor conditions, the usage time should be shortened. Replace immediately upon blockage alarm within the designed service life period. The blockage alarm setpoint for the oil filter element is typically 1.0–1.4 bar.

Hazards of using the oil filter element beyond its service life: insufficient oil return after blockage leads to excessive exhaust temperature, shortening the service life of the oil and oil separator element; insufficient oil return after blockage results in inadequate lubrication of the main unit, severely shortening its service life; if the filter element is damaged, unfiltered oil containing a large amount of metal particles and impurities enters the main unit, causing damage to the main unit.

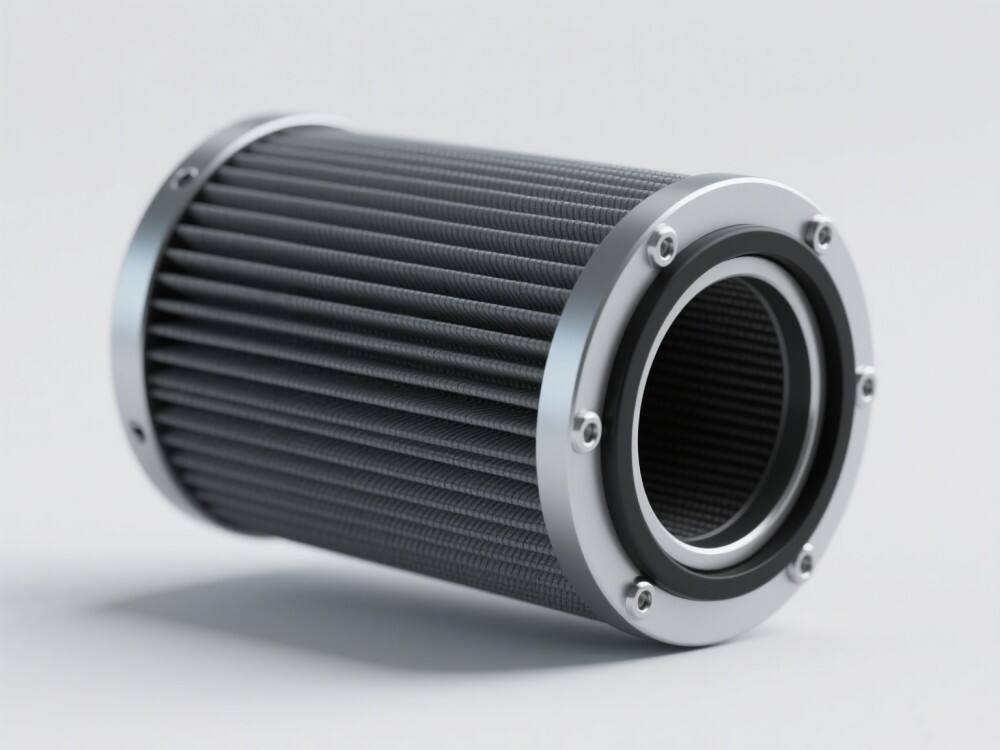

2. Air filter element: The air filter element is an important protective barrier for the air compressor! It removes dust and impurities from the air inhaled by the air compressor. The cleaner the inhaled air, the more assured the service life of the oil filter core, oil-air separator core, and oil; it prevents other foreign objects from entering the main unit, as the components of the main unit are extremely precise, with critical clearance gaps of 30-150µ. Therefore, the entry of foreign objects will inevitably cause damage to the main unit, leading to the main unit ‘seizing up’ or even becoming scrap.

Air filter core material: high-precision filter paper.

Air filter element material: high-precision filter paper. Air filter element replacement criteria: The replacement criteria for air filter elements are determined based on the designed service life of the air filter element and the air quality conditions of the compressor environment. Therefore, there are two scenarios where the air filter element needs to be replaced: Replace after the actual usage time reaches the designed service life. The designed service life of the air filter element is typically 2,000 hours, after which it should be replaced. If the actual air quality is good, the usage time can be extended based on the actual condition of the filter element, but the maximum extension should not exceed 1,000 hours. In environments with poor air quality, the usage time should be shortened. Replace immediately after a blockage alarm occurs within the design service life period. The blockage alarm set point for the air filter element is typically -0.05 bar. Risks of using an air filter element beyond its service life: insufficient airflow from the unit, affecting production; excessive pressure drop across the filter element, increasing unit load and reducing the service life of the main unit; increased actual compression ratio of the unit, increasing unit load and reducing the service life of the main unit: insufficient airflow from the unit, affecting production; excessive pressure drop across the filter element, increasing unit load and reducing the service life of the main unit; increased actual compression ratio of the unit, increasing unit load and reducing the service life of the main unit; damage to the filter element allowing foreign objects to enter the main unit, potentially causing the main unit to seize up or become scrap.

3. Air-Oil Separator element (oil separator): separates compressed air from oil. Oil-air separator core material: high-precision glass fibre. Oil-air separator core replacement criteria:

(1) Replace after the actual usage time reaches the designed service life. The typical service life of an oil-air separator core is 4,000–8,000 hours; it must be replaced upon expiration.

(2) Replace immediately upon blockage alarm within the designed service life period. The typical blockage alarm set point for an oil-air separator core is 0.8–1.0 bar. Hazards of using the oil-gas separation core beyond its service life: Poor separation efficiency, leading to high oil consumption and high oil content in compressed air, affecting the operation of downstream purification equipment and gas-using equipment; increased pressure drop after blockage, leading to increased actual exhaust pressure of the unit and increased energy consumption; after failure, glass fibre filtration and separation materials may detach and enter the oil, shortening the service life of the oil filter core and causing abnormal wear of the main unit.