Textile products come into direct contact with people, and their production processes rely on high-quality compressed air support. Oil-free air compressors are widely used across multiple industries including food, pharmaceuticals, rail transit, elec...

Learn More

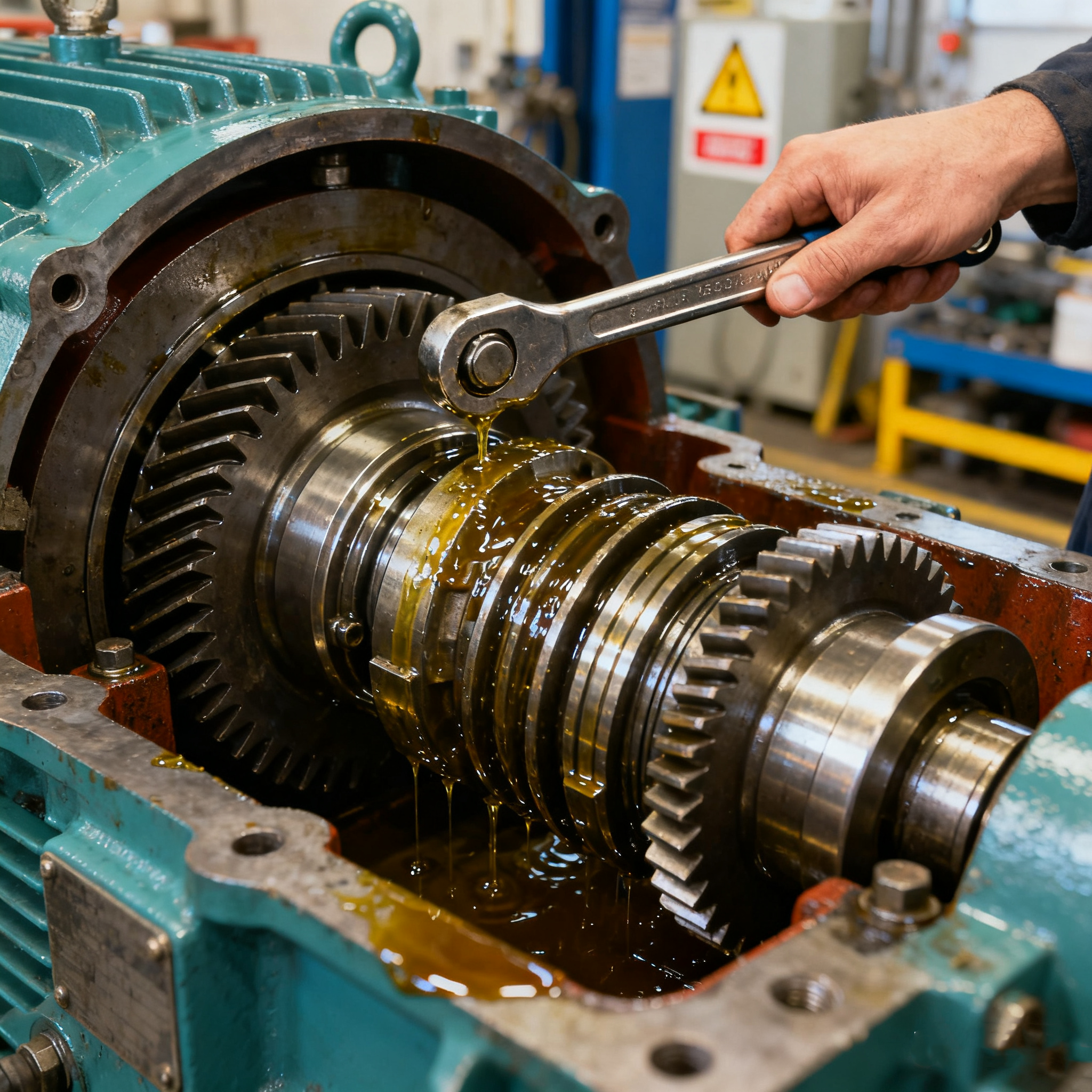

As a core high-efficiency air compression device in industrial production, abnormal increases in oil consumption in screw air compressors are a common pain point for users. This not only drives up operational costs but may also trigger equipment fail...

Learn More

Oil-injected screw air compressors are widely used in industrial production due to their highly efficient and stable operation. However, in actual operating conditions, frequent loading/unloading failures often occur, leading to issues such as freque...

Learn More

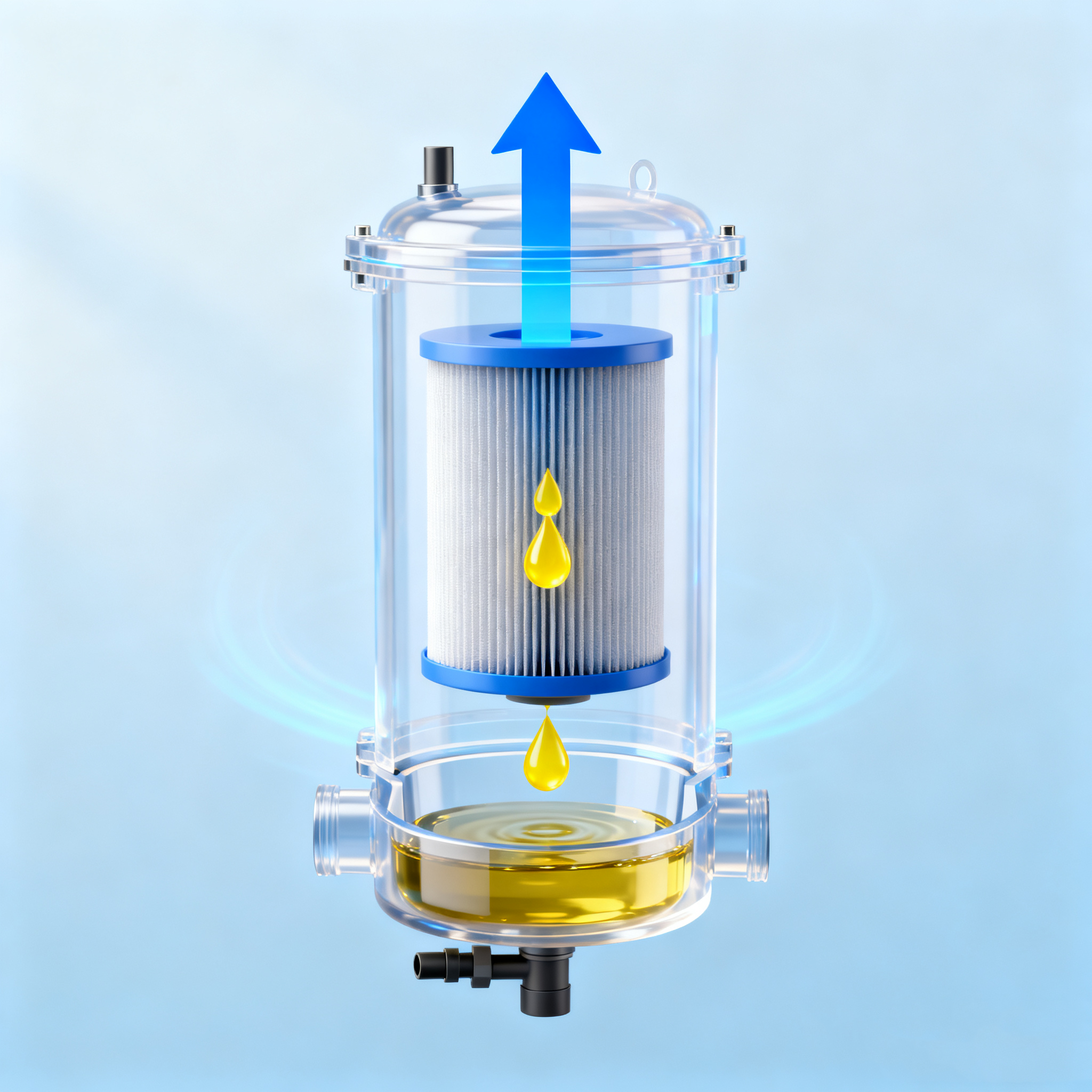

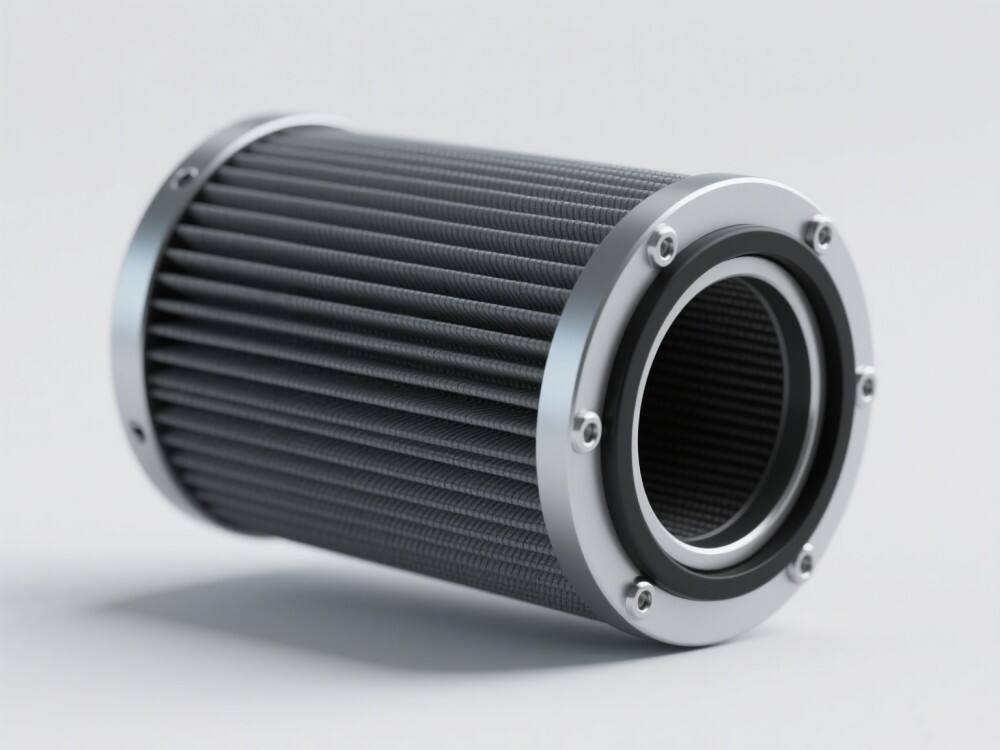

In an air compressor lubrication system, the oil filter is one of the three essential components that determine the reliability and cleanliness of the equipment—together with the air filter and the air-oil separator.A high-quality air compresso...

Learn More

Regular replacement of air compressor three filters is essential for ensuring stable unit operation and meeting the demands of air-consuming components. Below is the core information, presented concisely: I. Functions of the Three Filters and Risks o...

Learn More

I. Why Must Air Compressor Components Be Replaced on Schedule? The stable operation of screw air compressors hinges on the “health status” of core components—lubricants, filters, and other parts gradually wear out, become clogged, ...

Learn More

Choosing the Right Oil-Air Separator Filter Element: Don't Let Cheap, Low-Quality Products Ruin Your Air CompressorMany users report that filter elements seem expensive, but “you get what you pay for” is an industry truism—low...

Learn More

Persistence forges expertise, and expertise drives focus. To precisely address the industry pain point of oversized or undersized air compressor selection, we conducted in-depth research on compressors across brands, identifying three core prerequisi...

Learn More

The quality of screw air compressor oil plays a decisive role in the performance of oil-injected screw compressors. Premium oils must possess core characteristics such as strong oxidation resistance, rapid oil-gas separation, excellent anti-foaming p...

Learn More

Regardless of whether users employ oil-free air compressors, oil-lubricated air compressors, or air-cooled air compressors, prioritizing ventilation in the air compressor room is essential—this is a critical factor for ensuring stable equipment...

Learn More

Air compressor filter elements refer to oil filters, air filters, and oil separators. 1. Oil filter element: The function of the oil filter element is to remove metal particles and impurities from the special oil used in air compressors, ensuri...

Learn More

Screw compressors are positive displacement compressors that use two intermeshing screw rotors to compress gas. They are widely used in various fields due to their high efficiency, smooth operation, compact structure, and ability to adapt to a wide r...

Learn More