Choosing the Right Oil-Air Separator Filter Element: Don't Let Cheap, Low-Quality Products Ruin Your Air CompressorMany users report that filter elements seem expensive, but “you get what you pay for” is an industry truism—low...

Contact Us

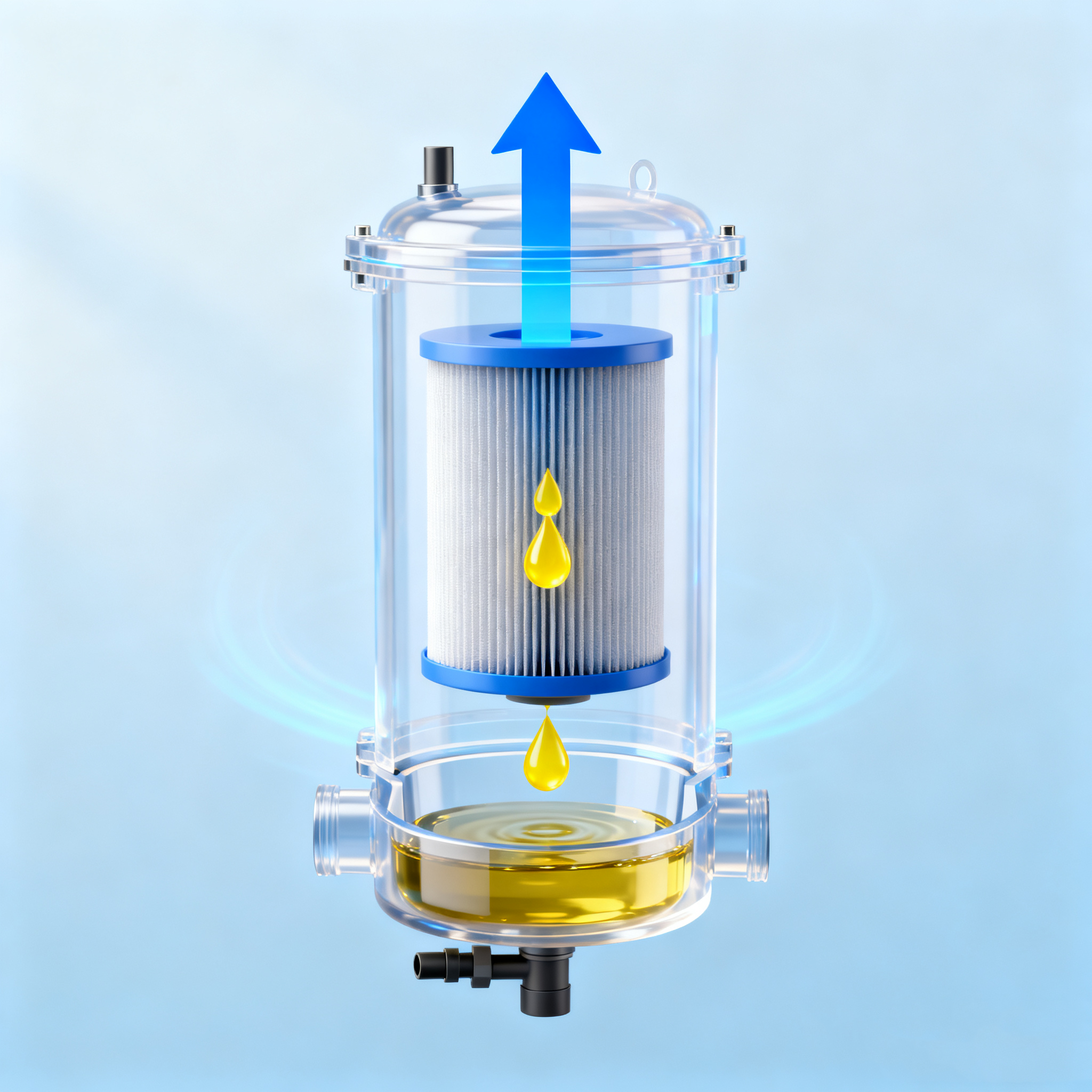

Choosing the Right Oil-Air Separator Filter Element: Don't Let Cheap, Low-Quality Products Ruin Your Air Compressor

Many users report that filter elements seem expensive, but “you get what you pay for” is an industry truism—low-cost, substandard filter elements may appear cost-effective, yet they significantly compromise quality. When selecting filter elements, it's crucial to carefully evaluate options to prevent issues that could disrupt air compressor operation and lead to greater losses.

Three Core Hazards of Substandard Filter Elements

1. Direct Damage to Compressor Host: Inferior filter elements fail to effectively trap contaminants, causing rapid oil contamination. Oil laden with coarse dust particles circulating internally can directly scratch the screw rotor surfaces. Minor damage may widen rotor clearances and increase operational noise, while severe cases can lead to complete screw host seizure and scrapping—resulting in extremely high repair costs.

2. Dramatically Reduced Compressor Oil Lifespan: The poor filtration efficiency of such filter paper allows large airborne dust particles to penetrate into the compressor. When mixed with the specialized oil—often referred to as the “lifeblood of compressors”—dust rapidly contaminates the oil, drastically shortening its service life. This necessitates frequent oil changes, ultimately increasing operational costs.

3. Triggering critical component failures: Substandard filters may cause carbon buildup inside heat exchangers, leading to blockages. They also interfere with the proper operation of thermostatic valve spools, causing spool jamming and erratic movement. This further compromises the compressor's heat dissipation and temperature control, triggering overall equipment malfunctions.