Maintaining optimal performance in your compressed air system requires regular attention to critical components, particularly the air compressor air filter. This essential element serves as the first line of defense against contaminants that could damage your equipment or compromise air quality. Industrial facilities across manufacturing, automotive, and food processing sectors rely heavily on clean, filtered compressed air to maintain operational efficiency and product quality standards.

Understanding when to replace your filtration components can prevent costly downtime, reduce energy consumption, and extend equipment lifespan. Many operators overlook subtle warning signs until system performance deteriorates significantly. Recognizing early indicators of filter degradation allows for proactive maintenance scheduling and prevents unexpected operational disruptions that could impact production schedules.

Professional maintenance teams emphasize the importance of systematic filter inspection protocols. Regular monitoring prevents contamination buildup that leads to reduced system efficiency and potential equipment failure. The following comprehensive analysis explores five critical warning signs that indicate immediate filter replacement requirements, helping facility managers optimize their compressed air systems effectively.

Performance Degradation Indicators

Reduced Air Flow and Pressure Drop

Decreased airflow represents one of the most noticeable symptoms of a compromised air compressor air filter. When filter media becomes saturated with contaminants, restricted airflow forces the compressor to work harder to maintain desired pressure levels. This increased workload results in elevated energy consumption and reduced overall system efficiency. Operators typically notice pressure fluctuations at point-of-use applications, indicating upstream filtration issues.

Measuring differential pressure across filter housings provides quantitative assessment of filter condition. Most manufacturers specify maximum allowable pressure drops, typically ranging from 5 to 15 PSI depending on filter type and application requirements. Exceeding these thresholds indicates immediate replacement necessity to prevent system strain and maintain optimal performance characteristics.

Professional technicians recommend installing permanent pressure monitoring equipment to track filter performance continuously. Digital gauges with alarm capabilities alert operators when pressure differentials exceed predetermined limits. This proactive approach prevents unexpected system failures and allows for scheduled maintenance during planned downtime periods, minimizing operational impact.

Increased Energy Consumption Patterns

Energy consumption analysis reveals significant insights into filter performance degradation. Clogged filters force compressors to operate at higher duty cycles to maintain required pressure levels, resulting in measurable increases in electrical consumption. Facility energy management systems can identify these trends through comparative analysis of historical power usage data.

Motor amperage readings provide real-time indicators of compressor loading conditions. Gradual increases in current draw often correlate with filter restriction development. Experienced maintenance personnel monitor these parameters during routine inspections, documenting trends that predict filter replacement timing. Early intervention based on energy consumption patterns prevents excessive operating costs and equipment stress.

Implementing energy monitoring protocols helps establish baseline consumption patterns for different operational scenarios. Deviations from established norms trigger investigation procedures that often identify filter-related issues before they impact production quality or equipment reliability. This data-driven approach optimizes maintenance scheduling and reduces unexpected repair costs.

Visual and Physical Inspection Signs

Filter Element Discoloration and Contamination

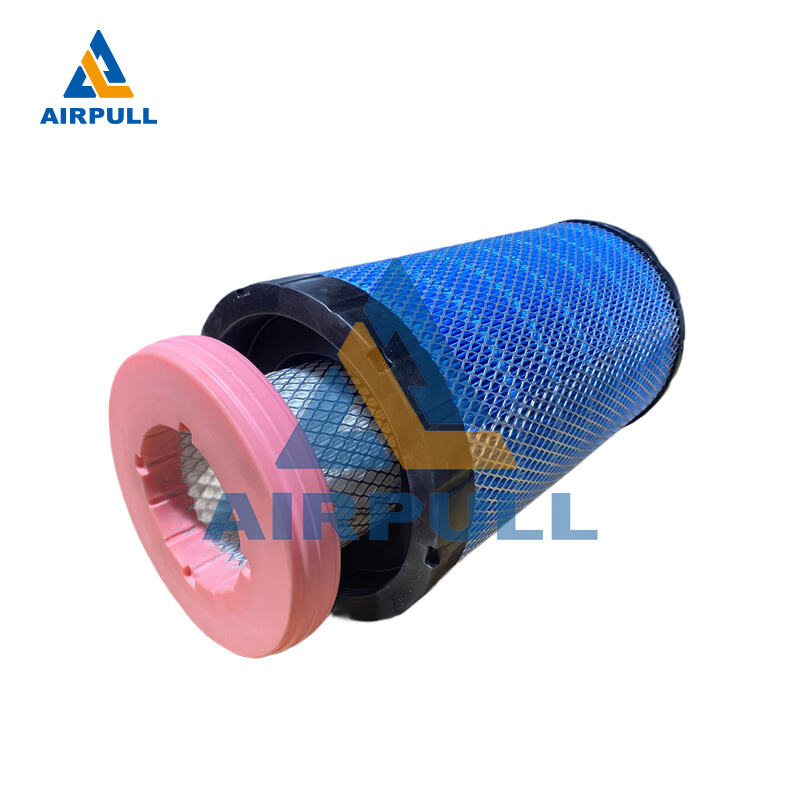

Visual inspection of filter elements reveals critical information about contamination levels and replacement necessity. Clean filters typically maintain their original color, while used elements show progressive darkening from accumulated particles and contaminants. Severe discoloration indicates saturation beyond effective filtration capacity, requiring immediate replacement to restore system performance.

Different contaminant types produce distinct visual signatures on filter media. Oil aerosols create glossy, dark staining patterns, while particulate matter results in uniform gray or brown coloration. Water contamination often appears as rust-colored deposits or crystalline formations on synthetic media. Understanding these visual indicators helps maintenance teams identify contamination sources and implement appropriate corrective measures.

Professional inspection protocols include photographic documentation of filter conditions to establish replacement intervals and track contamination trends. This historical data assists in optimizing filter selection for specific environmental conditions and operational requirements. Regular visual assessments complement pressure monitoring systems to provide comprehensive filter performance evaluation.

Physical Damage and Structural Integrity

Physical damage to filter housings or elements compromises filtration effectiveness and indicates immediate replacement requirements. Cracked housings allow unfiltered air bypass, while torn or collapsed filter media permits contaminant passage downstream. These conditions create potential equipment damage risks and air quality degradation that affects production processes.

Vibration-induced damage commonly affects air compressor air filter installations in industrial environments. Loose mounting hardware or inadequate support structures allow excessive movement that leads to premature failure. Regular inspection of mounting systems and proper installation techniques prevent these issues and extend filter service life significantly.

Thermal cycling effects cause expansion and contraction stress in filter components, particularly in applications with variable temperature conditions. Repeated thermal stress can compromise seal integrity and create bypass pathways. Monitoring ambient temperature variations helps predict thermal stress impacts and adjust replacement schedules accordingly for optimal system protection.

Air Quality Deterioration Symptoms

Contamination in Downstream Applications

Contamination appearance in downstream applications signals filter breakthrough and immediate replacement necessity. Manufacturing processes requiring clean compressed air show quality degradation when filtration systems fail to remove particles, oil vapors, or moisture effectively. Product defects, surface contamination, or process inconsistencies often trace back to inadequate air filtration upstream.

Laboratory analysis of compressed air samples provides quantitative assessment of contamination levels compared to application requirements. ISO 8573 standards define air quality classes for different purity levels, helping operators select appropriate filtration strategies. Regular air quality testing identifies filter performance degradation before it impacts critical production processes or product quality standards.

Point-of-use monitoring equipment detects real-time contamination levels at critical application points. Particle counters, oil vapor analyzers, and moisture sensors provide continuous feedback on air quality conditions. Alert systems notify operators when contamination levels exceed acceptable limits, triggering immediate investigation and corrective action procedures.

Odor and Moisture Detection

Unusual odors in compressed air lines indicate filter saturation with organic contaminants or microbial growth within filter housings. Oil-saturated filters often produce characteristic petroleum odors, while biological contamination creates musty or sour smells. These conditions compromise air quality and may pose health risks in sensitive applications like food processing or pharmaceutical manufacturing.

Excessive moisture downstream of filtration systems suggests filter media saturation or inadequate drainage from filter housings. Water accumulation promotes microbial growth and corrosion in air distribution systems. Proper drainage protocols and regular inspection of automatic drain valves prevent these issues and maintain optimal filter performance characteristics.

Environmental monitoring systems track humidity levels and detect moisture breakthrough in compressed air systems. Dew point measurements provide quantitative assessment of moisture removal effectiveness. Trending this data helps optimize filter replacement schedules and identify potential system design improvements for enhanced moisture control capabilities.

Maintenance Schedule Considerations

Operating Environment Impact

Environmental conditions significantly influence filter replacement frequency requirements. Dusty industrial environments accelerate particulate loading, while high humidity conditions promote moisture accumulation and potential microbial growth. Chemical processing facilities may encounter corrosive atmospheres that degrade filter media more rapidly than standard applications.

Seasonal variations affect contamination patterns and filter performance characteristics. Summer months typically increase dust loading from construction activities and agricultural operations, while winter conditions may introduce salt contamination in coastal areas. Understanding these cyclical patterns helps maintenance teams anticipate replacement needs and adjust schedules accordingly.

Indoor air quality monitoring provides valuable data for optimizing filter selection and replacement intervals. Particle counting equipment and atmospheric monitoring systems track ambient contamination levels that directly impact filter loading rates. This environmental data supports predictive maintenance strategies and helps justify upgraded filtration systems for challenging operating conditions.

Operational Duty Cycle Analysis

Compressor operating patterns directly influence filter contamination rates and replacement schedules. Continuous operation systems accumulate contaminants steadily, while intermittent duty cycles may experience condensation issues during startup periods. Understanding operational profiles helps establish realistic maintenance intervals and prevents unexpected filter failures.

Load variation analysis reveals peak demand periods that stress filtration systems beyond normal capacity. High-flow conditions accelerate filter loading and may require more frequent replacement intervals. Monitoring system demand patterns helps identify opportunities for filter sizing optimization or parallel installation configurations to handle peak loads effectively.

Predictive maintenance algorithms incorporate operational data to forecast filter replacement timing accurately. Machine learning systems analyze historical performance patterns, environmental conditions, and operational parameters to optimize maintenance schedules. This data-driven approach reduces maintenance costs while ensuring reliable system performance and air quality standards.

FAQ

How often should air compressor air filters be replaced

Replacement frequency depends on operating conditions, environmental factors, and filter type. Standard inlet filters typically require replacement every 1000-2000 operating hours, while high-efficiency filters may last longer in clean environments. Monitor differential pressure and visual condition rather than relying solely on time-based schedules. Severe operating conditions may require monthly replacement, while clean environments might extend intervals to quarterly or semi-annually.

What happens if filters are not replaced promptly

Delayed replacement leads to reduced system efficiency, increased energy consumption, and potential equipment damage. Clogged filters force compressors to work harder, increasing operating costs and reducing component lifespan. Contamination bypass can damage downstream equipment and compromise product quality in manufacturing applications. Catastrophic filter failure may allow debris to enter the compression chamber, causing expensive internal damage requiring major repairs.

Can filters be cleaned instead of replaced

Some filter types allow cleaning, but effectiveness diminishes with each cleaning cycle. Fabric and some synthetic media can be cleaned with compressed air or washing, though this may compromise filtration efficiency. Paper and fiberglass elements cannot be effectively cleaned and must be replaced. Even cleanable filters eventually require replacement as media degrades. Consider lifecycle costs when evaluating cleaning versus replacement options.

How do you select the right replacement filter

Match filter specifications to original equipment requirements, including physical dimensions, filtration efficiency, and flow capacity ratings. Consider operating conditions such as temperature, pressure, and contamination levels when selecting upgrade options. Verify compatibility with existing housing hardware and sealing systems. Consult manufacturer specifications and consider higher efficiency options if air quality requirements have increased since original installation.