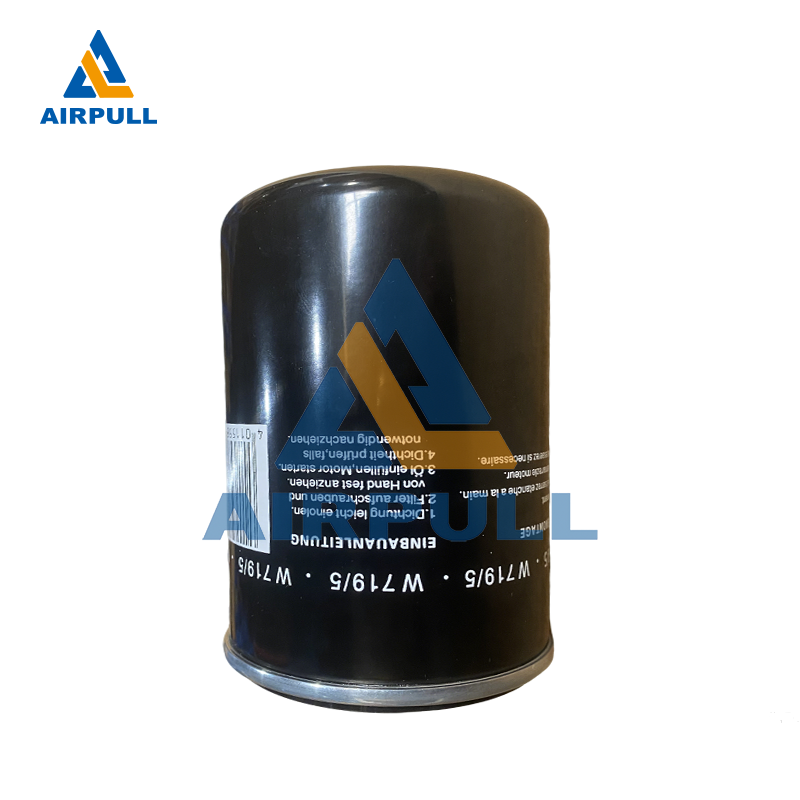

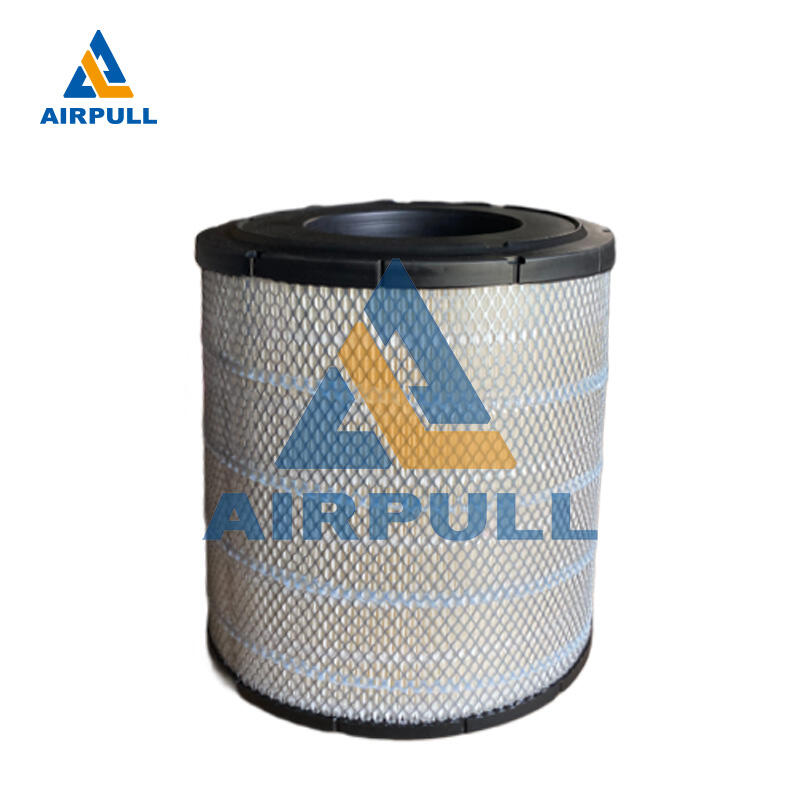

screw compressor spare parts

Screw compressor spare parts represent essential components that ensure the optimal performance and longevity of industrial compression systems. These precision-engineered parts include rotors, bearings, seals, oil filters, separation elements, and control systems, each playing a crucial role in maintaining efficient operation. The primary function of these components is to facilitate the compression process while minimizing energy consumption and maintaining system reliability. Modern screw compressor spare parts are manufactured using advanced materials and cutting-edge technology, incorporating features such as wear-resistant coatings, precision-machined surfaces, and optimized geometries. These parts are designed to withstand high pressures, temperatures, and continuous operation in demanding industrial environments. Applications span across various industries, including manufacturing, petrochemical processing, food and beverage production, and pharmaceutical manufacturing. The parts are engineered to meet strict quality standards and specifications, ensuring compatibility with different compressor models and brands. Regular replacement and maintenance of these components are crucial for preventing unexpected downtime and maintaining consistent performance levels.