screw air compressor parts

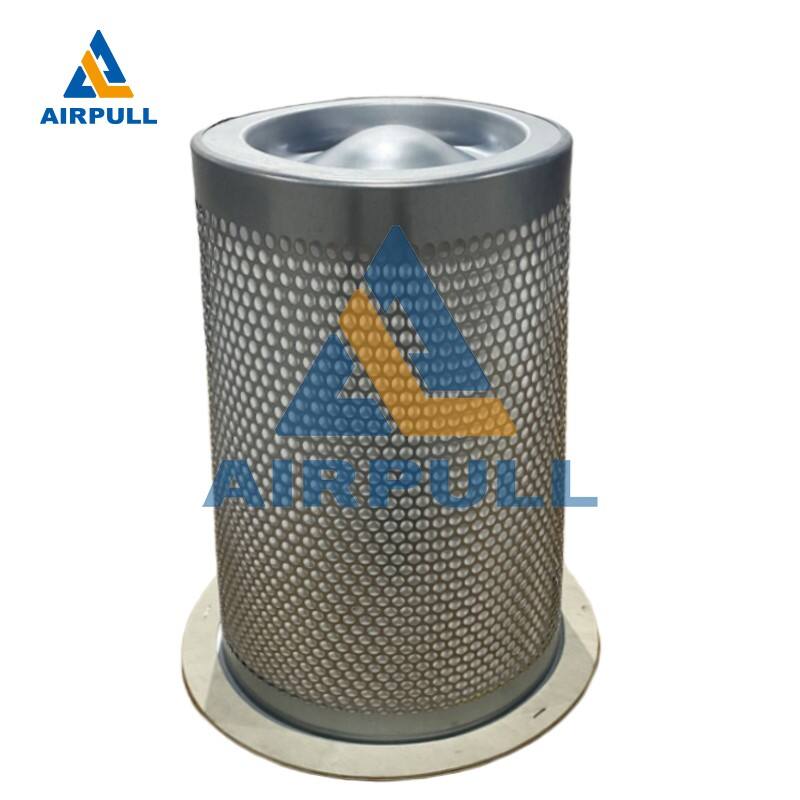

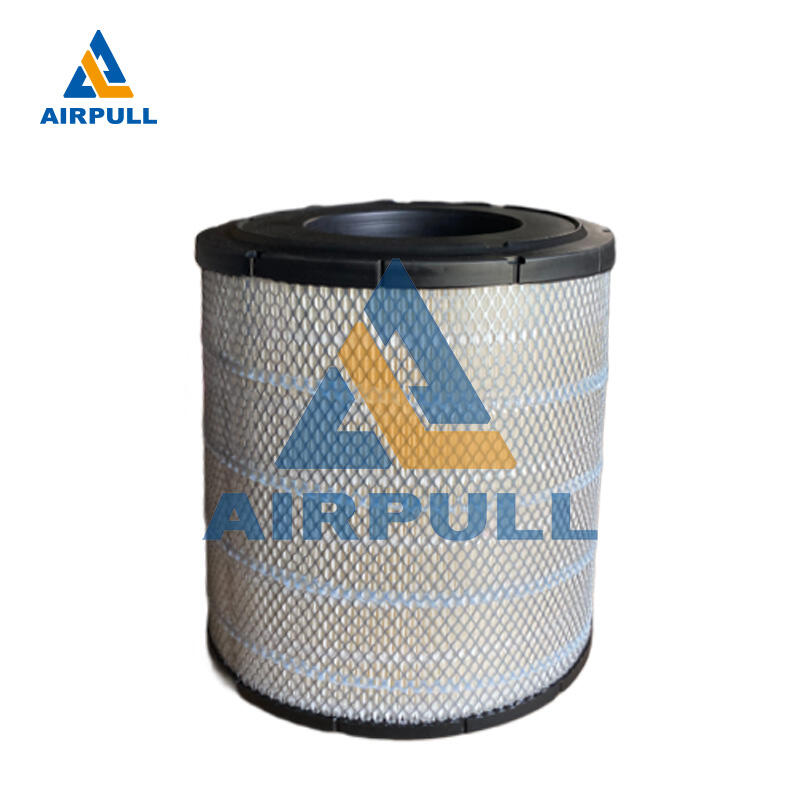

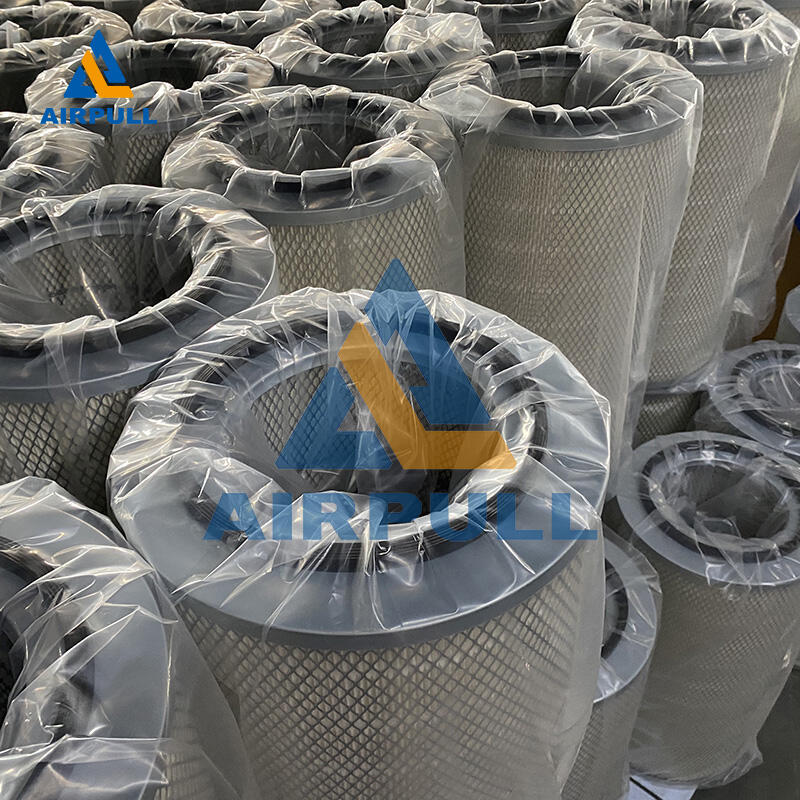

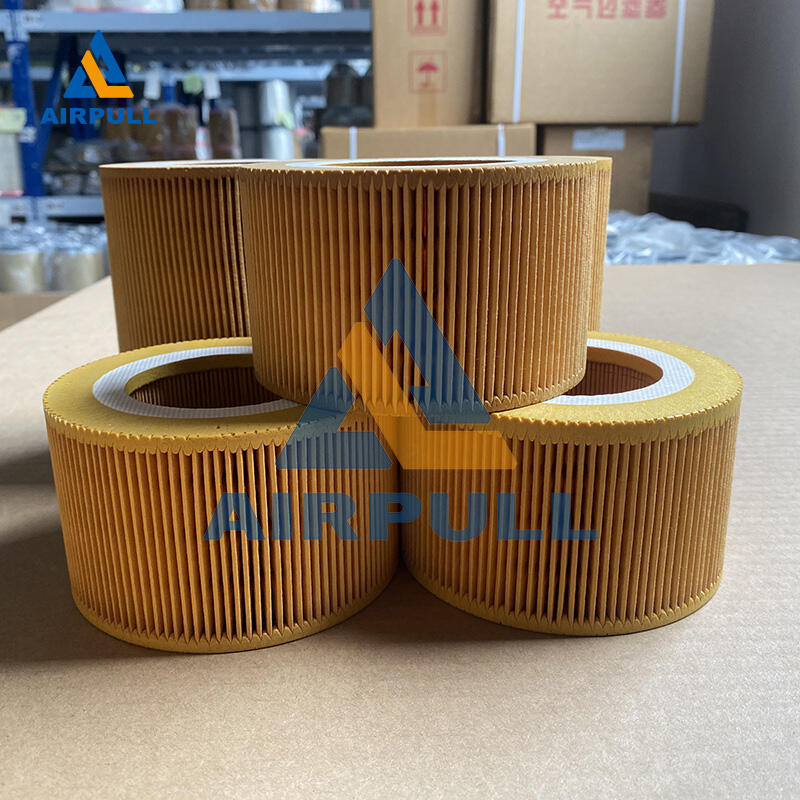

Screw air compressor parts constitute a sophisticated system of components working in harmony to deliver reliable compressed air. The assembly comprises essential elements including the air end, which houses the male and female rotors that perform the primary compression function. These precision-engineered rotors, typically crafted from high-grade steel, mesh together to create progressive compression chambers. The intake valve regulates airflow into the system, while the oil separation system ensures clean air output by removing oil particles from the compressed air stream. The cooling system, incorporating both air and oil coolers, maintains optimal operating temperatures. Electronic controls monitor and adjust performance parameters, ensuring efficient operation. The air-oil reservoir separates and stores oil for recirculation, while the minimum pressure valve maintains system pressure. These components work together to provide consistent air pressure for industrial applications, from powering pneumatic tools to supporting manufacturing processes. The motor drive system, typically featuring variable speed capability, powers the rotors while optimizing energy consumption. Air filters protect internal components from contamination, and the discharge system safely channels compressed air to its intended application. This integrated system delivers reliable performance while minimizing maintenance requirements and maximizing operational efficiency.