screw compressor components

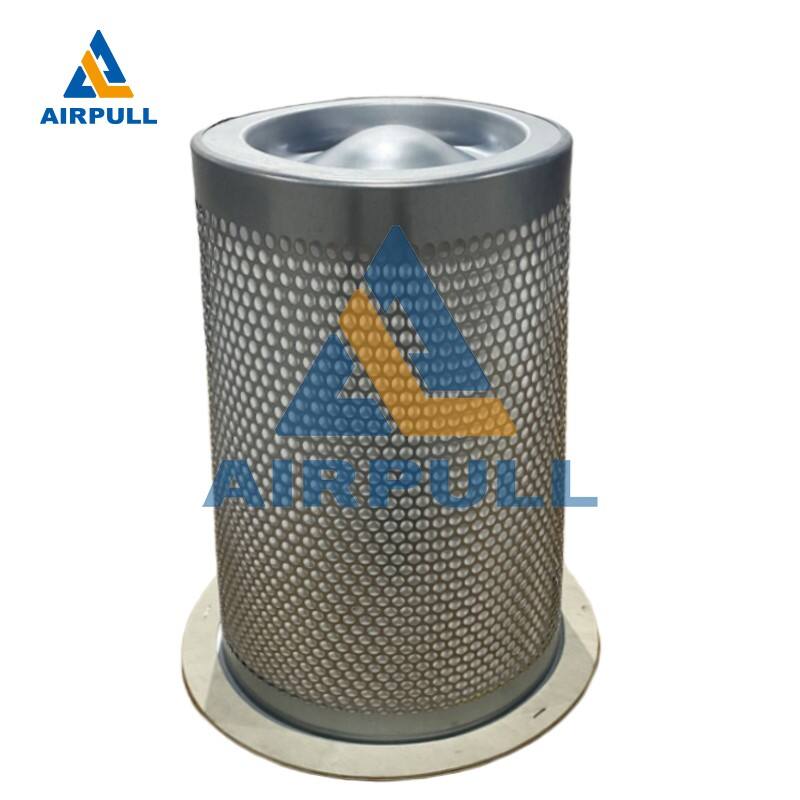

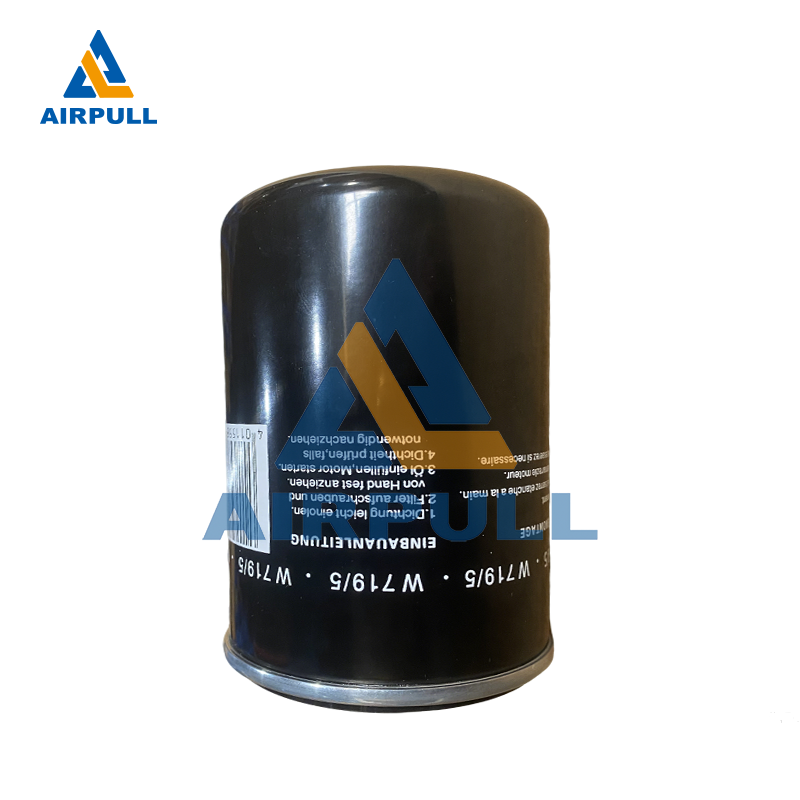

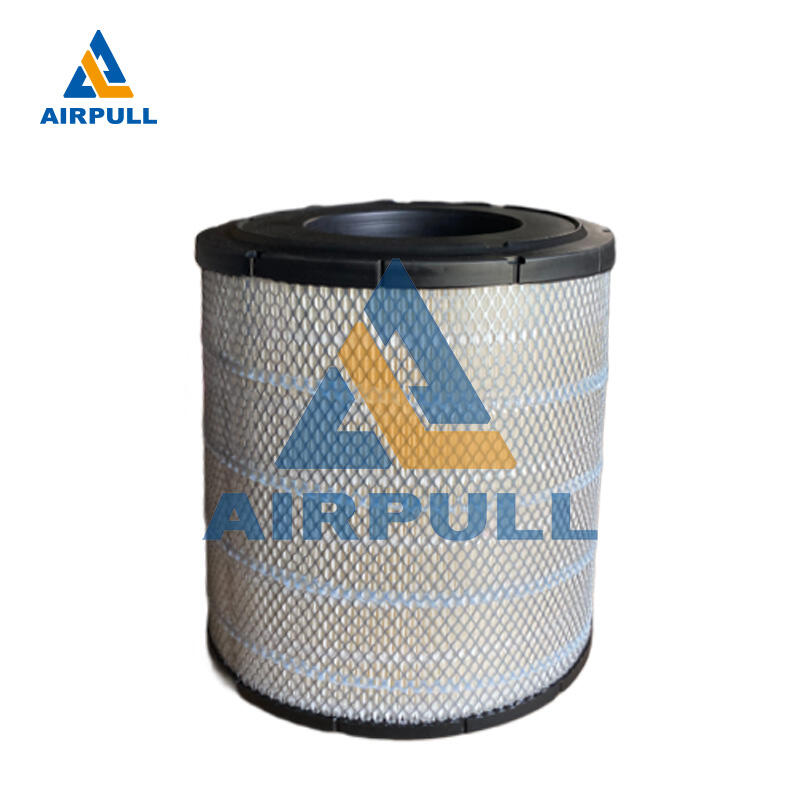

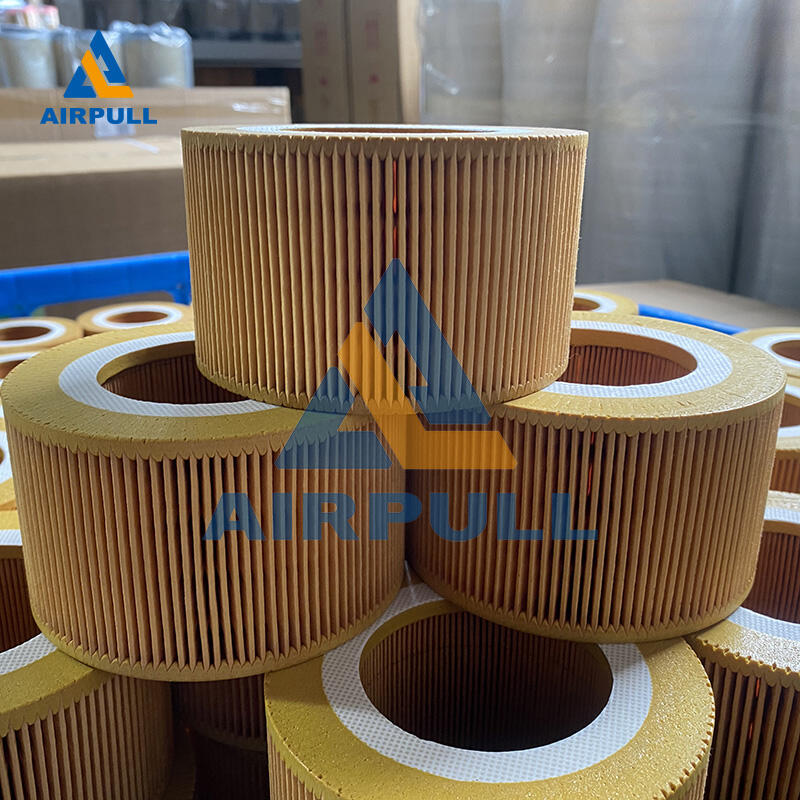

Screw compressor components represent a sophisticated assembly of precision-engineered parts that work together to deliver reliable compressed air solutions. At the heart of the system are the male and female rotors, precision-machined helical screws that mesh together to create progressive compression chambers. The intake port allows air to enter these chambers, while the discharge port releases the compressed air. Essential components include the housing unit, which contains the rotors and provides structural integrity, and the bearing system that supports the rotor shafts. The oil injection system plays a crucial role in lubricating, cooling, and sealing the compression chamber. Modern screw compressors also feature advanced control systems, including pressure sensors, temperature monitors, and electronic controllers that optimize performance and efficiency. The air-oil separation system ensures clean compressed air output by removing oil particles from the discharged air. Additionally, the cooling system, typically comprising oil coolers and aftercoolers, maintains optimal operating temperatures. These components work in harmony to provide efficient, reliable, and continuous compressed air supply for various industrial applications, from manufacturing and processing to power generation and construction equipment.