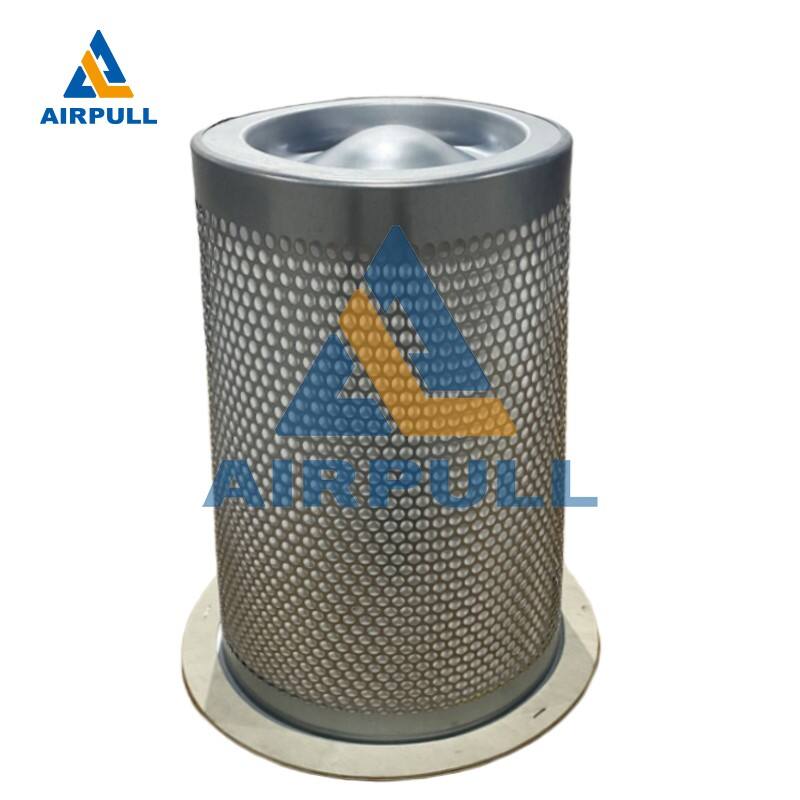

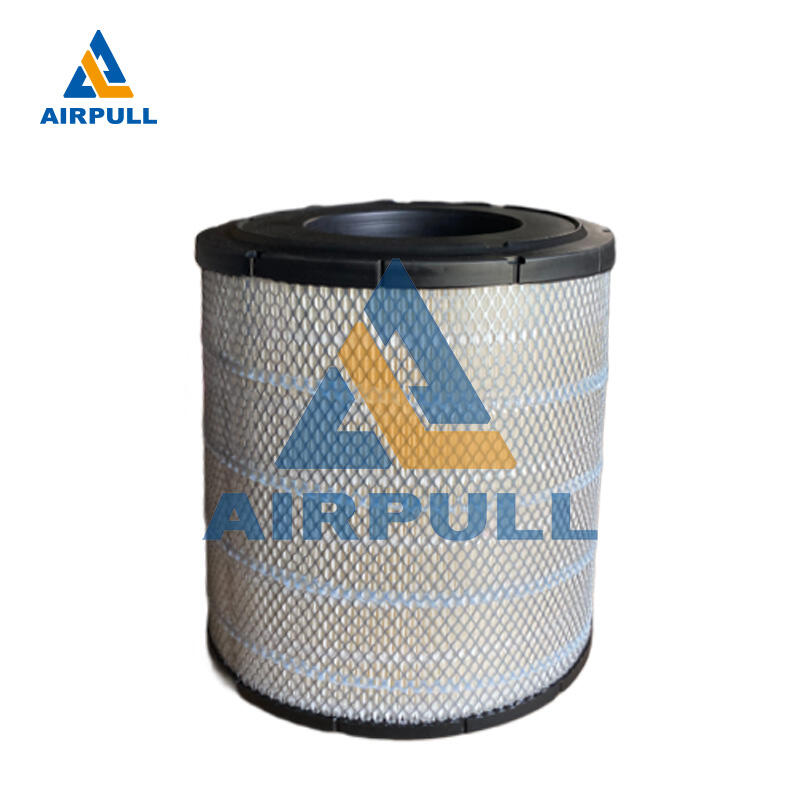

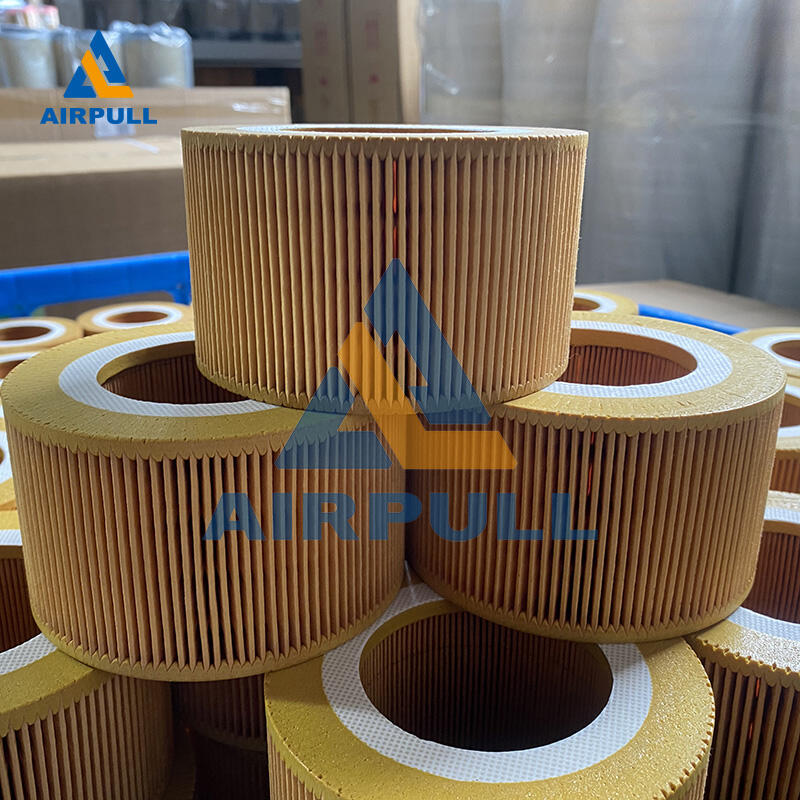

rotary screw compressor parts

Rotary screw compressor parts represent the core components of modern industrial compression systems. These essential elements work together seamlessly to deliver reliable compressed air through a sophisticated mechanism of intermeshing helical screws. The primary components include the air end, which houses the male and female rotors, the intake valve that regulates air flow, the oil separation system that ensures clean air output, and the cooling system that maintains optimal operating temperatures. The precision-engineered rotors, typically manufactured from high-grade steel, rotate in opposite directions to create progressive compression chambers. This design enables continuous compression, resulting in steady airflow and efficient operation. The lubrication system, incorporating oil filters and coolers, plays a crucial role in maintaining component longevity and operational efficiency. Modern rotary screw compressor parts often feature advanced materials and coatings that enhance durability and reduce friction, contributing to extended service life and reduced maintenance requirements. These components find extensive applications across various industries, from manufacturing and construction to food processing and pharmaceutical production, where reliable compressed air is essential for operations.