Established in 1996, Xinxiang Airpull Filter Co., Ltd. has dedicated itself to the mission of "Filtering the World, Purifying the Future." Leveraging nearly 30 years of technological expertise, we have evolved into a national high-tech enterprise integrating cutting-edge R&D, intelligent manufacturing, global marketing, and technical services.

Years of Industry Expertise

Dedicated Professionals

Product Categories

New Product Development

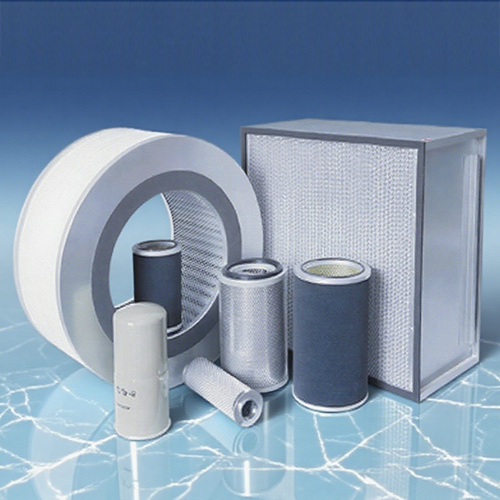

Air Filter/Filter Element

Air Filter/Filter Element

Air filters remove dust from the air through interception, collision, diffusion, and electrostatic adsorption, ensuring that clean gas enters the compressor system, reducing component wear and contamination, and extending the service life of components such as the compressor head, bearings, and oil-gas separation core.

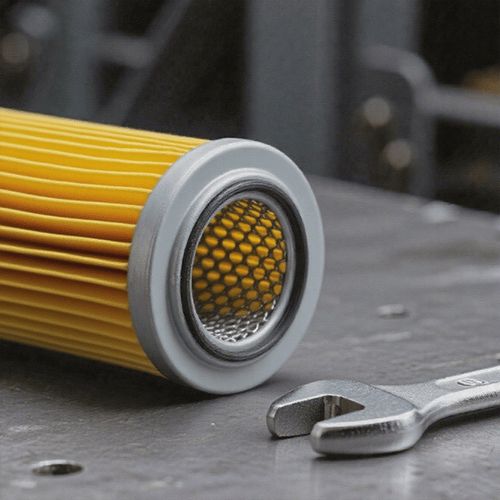

Lubricating Oil Filter/ Filter Element

Lubricating Oil Filter/ Filter Element

Lubricating oil filters primarily remove solid particles, impurities, and degraded oil components from lubricating oil, ensuring reliable operation of screw compressor rotors and preventing scale buildup in oil cooling pipes.

Air-Oil Separator/Filter Element

Air-Oil Separator/Filter Element

The oil-gas separator filter element separates the oil-gas mixture discharged from the air compressor main unit: oil droplets are separated by a micron-level glass fibre layer, coalesce into larger oil droplets, and then, under the influence of gravity, collect at the bottom and flow back to the compressor oil circuit via the return oil pipe.

Compressor Lubricating Oil

Compressor Lubricating Oil

AIRPULL R&D center features an in-house laboratory dedicated to lubricating oil products, holding ISO-compliant third-party testing certifications. Our engineers can readily tailor product solutions—whether by analyzing your original samples or based on your products' application scenarios and equipment models.

Vacuum Assisted Oil Mist Filter

Vacuum Assisted Oil Mist Filter

Vacuum-assisted oil mist filters are specifically designed for crankcase ventilation filtration systems in engines or turbines to address oil mist emissions and control system pressure.

Exhaust Oil Mist Filter

Exhaust Oil Mist Filter

Captures oil mist particles from the exhaust port of an oil-type vacuum pump and recycles them to prevent environmental pollution;

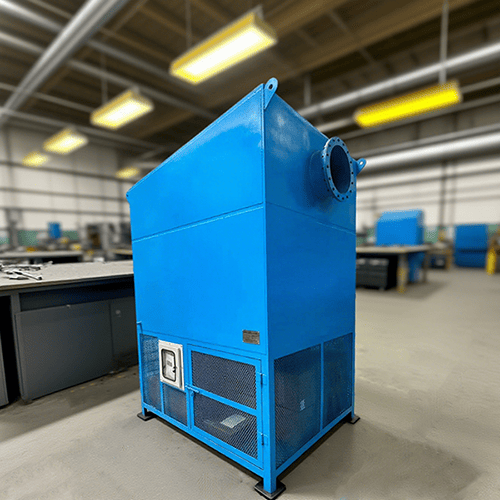

Self-Cleaning Air Filter

Self-Cleaning Air Filter

Self-cleaning air filters are a new type of filter with automatic dust removal capabilities, enabling continuous air purification over extended periods. They remove dust and other impurities from the gas stream, ensuring that clean air enters the equipment.

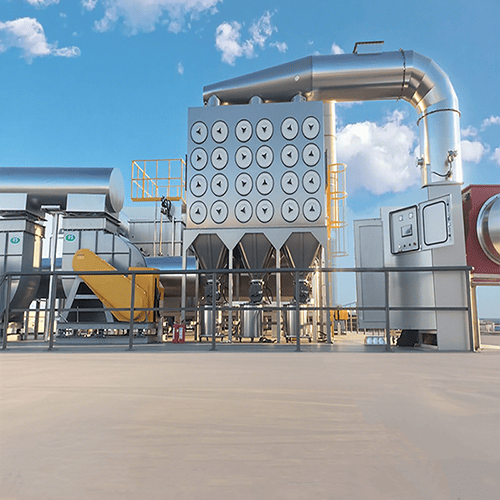

Industrial Purification Equipment

Industrial Purification Equipment

Our environmental products including: self-cleaning air filters, weld fume filter,incision dust collector, sand dust collector, activated carbon adsorption tank, RCO, RTO, TO, spray tower etc.

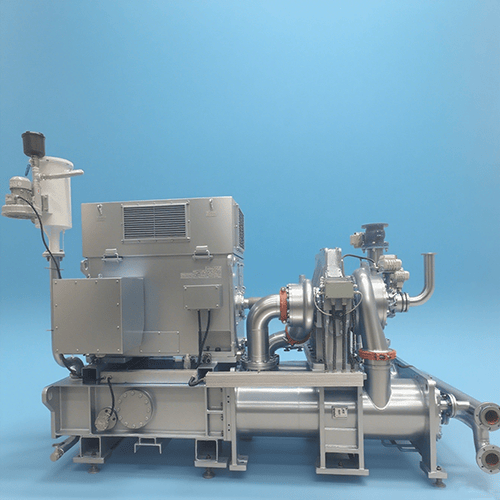

Centrifugal Compressor Filter/ Filter Element

Centrifugal Compressor Filter/ Filter Element

As centrifugal technology in the compressor industry continues to mature, the application scope of centrifugal air compressors is becoming increasingly widespread. To precisely address market demands and users' core requirements for energy efficiency and environmental protection, we remain committed to our mission of ‘delivering cleaner air to users.’ We have developed and designed filtration products tailored to specific operating conditions, with the following key features:

Vacuum Pre-filter

Vacuum Pre-filter

The vacuum pre-filter is installed at the front end of the vacuum pump inlet. Its primary function is to filter dust and small amounts of liquid from the gas, thereby protecting the vacuum pump rotor and preventing damage caused by the ingress of contaminants. When the vacuum pump starts operating, solid dust particles in the gas are trapped on the surface of the filter media, while small amounts of liquid are filtered, condensed, and settle at the bottom of the filter housing, ultimately being discharged through the liquid drainage pipe; clean gas then flows smoothly into the vacuum pump, effectively preventing wear and corrosion of the pump's moving parts.

With 30 years of industry-specific expertise, Airpull runs an accredited ISO-certified lab and a dedicated R&D center, investing 3% of its annual revenue.

We offer comprehensive OEM & ODM services to all customers, tailoring exclusive solutions free of charge to meet their specific requirements.

We are a manufacturer of high-quality filtration products and offer free samples. Contact us today to request yours.

Contact us anytime, 24/7, for complimentary support with Airpull product information or after-sales service.

As a quality manufacturer, Airpull provides reliable solutions across sectors including industrial engineering, medical, and power.

To facilitate more efficient collaboration, we accept various payment methods, including wire transfer (T/T), letter of credit (L/C), Western Union, and PayPal.