Understanding the Critical Role of Oil Separation Systems

In the world of industrial machinery and compressed air systems, the air oil separator filter stands as a crucial component that ensures optimal performance and longevity of equipment. These sophisticated filtration devices work tirelessly to remove oil particles from compressed air streams, maintaining system efficiency and preventing contamination. Without proper maintenance, even the most advanced air oil separator filter can fail to perform its essential functions, leading to decreased system efficiency and potential equipment damage.

Modern industrial operations rely heavily on clean, oil-free compressed air for various applications. From manufacturing facilities to processing plants, the quality of compressed air directly impacts product quality, operational efficiency, and equipment lifespan. This makes the maintenance of air oil separator filters not just a routine task, but a critical aspect of facility management.

Components and Functionality of Separation Systems

Core Elements of Air Oil Separator Filters

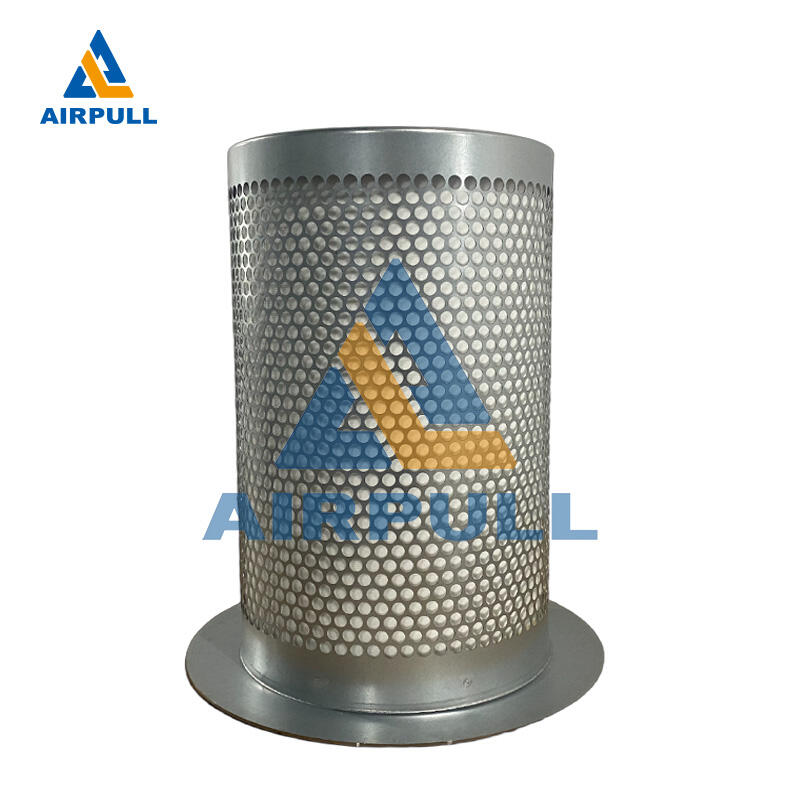

The air oil separator filter consists of several key components working in harmony to achieve efficient oil separation. The primary filtration medium is typically made from high-grade synthetic materials designed to capture oil particles while allowing clean air to pass through. The housing unit provides structural support and ensures proper air flow direction, while the drainage system collects and returns separated oil to the system.

Advanced separator designs incorporate multiple stages of filtration, each targeting different particle sizes and types of contamination. This layered approach ensures maximum efficiency in removing oil aerosols, liquid oil, and other contaminants from the compressed air stream.

Operating Principles and Performance Factors

The operation of an air oil separator filter relies on several physical principles, including coalescence, gravity separation, and mechanical filtration. As compressed air flows through the system, oil particles collide with filter fibers, combine into larger droplets, and are effectively separated from the airstream. Understanding these principles is crucial for maintaining optimal performance and implementing effective maintenance strategies.

Environmental conditions, operating temperatures, and system pressure all play significant roles in filter performance. Regular monitoring of these parameters helps identify potential issues before they impact system efficiency.

Maintenance Best Practices

Regular Inspection Protocols

Implementing a systematic inspection routine for your air oil separator filter is fundamental to preventing system failures. Visual inspections should check for obvious signs of wear, damage, or oil accumulation. Pressure differential readings across the filter provide valuable information about its condition and remaining service life.

Documentation of inspection results helps establish performance trends and anticipate maintenance needs. This proactive approach reduces unexpected downtime and extends equipment life.

Cleaning and Replacement Guidelines

While some air oil separator filters are designed for replacement rather than cleaning, certain models can be maintained through careful cleaning procedures. Following manufacturer specifications for cleaning methods and materials is essential to avoid damaging the filtration media. The frequency of cleaning or replacement depends on operating conditions, usage patterns, and filter specifications.

When replacement becomes necessary, selecting the correct filter specification and following proper installation procedures ensures optimal performance. Keep detailed records of replacement dates and observed conditions to refine maintenance schedules.

Optimizing System Performance

Efficiency Enhancement Strategies

Maximizing the efficiency of your air oil separator filter involves more than basic maintenance. Operating the system within designed parameters, maintaining appropriate temperatures, and ensuring proper oil levels all contribute to optimal separation efficiency. Regular analysis of separated oil quality can provide insights into system health and potential optimization opportunities.

Advanced monitoring systems can track performance metrics in real-time, allowing for immediate response to efficiency changes. This data-driven approach helps maintain peak performance while minimizing energy consumption.

Preventive Maintenance Planning

Developing a comprehensive preventive maintenance program for air oil separator filters requires careful consideration of operating conditions, manufacturer recommendations, and system requirements. This includes scheduling regular inspections, planning maintenance activities during planned downtime, and maintaining adequate spare parts inventory.

Training maintenance personnel in proper procedures and troubleshooting techniques ensures consistent quality of maintenance work. Regular review and updating of maintenance protocols help incorporate new best practices and technological advances.

Troubleshooting Common Issues

Identifying Performance Problems

Common indicators of air oil separator filter issues include increased oil consumption, decreased air quality, and rising operating temperatures. Understanding these warning signs allows for early intervention before major problems develop. Regular testing of compressed air quality helps identify deteriorating filter performance.

Systematic troubleshooting approaches help isolate problems quickly and accurately. This includes checking pressure differentials, inspecting drainage systems, and evaluating overall system operation.

Implementing Solutions

Once problems are identified, implementing appropriate solutions quickly minimizes system impact. This may involve filter cleaning, replacement, or adjusting operating parameters. Following manufacturer guidelines for repair procedures ensures safe and effective problem resolution.

Documenting problems and solutions creates a valuable knowledge base for future reference. This information helps refine maintenance procedures and prevent recurring issues.

Frequently Asked Questions

How often should an air oil separator filter be replaced?

The replacement interval for an air oil separator filter typically ranges from 2,000 to 8,000 operating hours, depending on operating conditions, system design, and manufacturer recommendations. Regular monitoring of pressure differential and air quality helps determine optimal replacement timing.

What are the signs of a failing air oil separator filter?

Key indicators include increased oil consumption, excessive pressure differential across the filter, decreased compressed air quality, and visible oil carryover in the air system. Regular monitoring helps detect these signs early.

Can air oil separator filters be cleaned and reused?

While some models can be cleaned according to manufacturer specifications, many modern air oil separator filters are designed for replacement only. Attempting to clean non-cleanable filters can damage the filtration media and compromise system performance. Always consult manufacturer guidelines before attempting to clean any filter.